Stainless steel is a versatile and corrosion-resistant alloy composed primarily of iron, chromium (minimum 10.5%), and often other elements like nickel, molybdenum, or carbon. Its unique properties make it indispensable across industries. Below are key applications categorized by sector:

1. Architecture & Construction

Structural elements: Bridges (e.g., Helix Bridge Singapore), building façades (e.g., Chrysler Building cladding)

Functional components: Elevator panels, roofing (e.g., Disney Concert Hall), rebar for concrete in coastal areas

Aesthetic features: Decorative handrails, sculptural installations (e.g., Chicago Cloud Gate)

Why: Combines strength (yield strength up to 2,000 MPa in duplex grades) with weather resistance (forms passive Cr₂O₃ layer)

2. Medical & Healthcare

Surgical tools: Scalpels, forceps (316L grade for superior corrosion resistance)

Implants: Hip joints (low-carbon 316LV), bone screws (nickel-free grades like 1.4441 for allergy prevention)

Equipment: MRI machines (non-magnetic austenitic grades), sterilization autoclaves

Critical factor: ASTM F138/F139 compliance for biocompatibility

3. Food & Beverage Industry

Processing: Brewery fermentation tanks (304L), dairy pasteurizers

Transport: Food-grade pipelines (electropolished 316 interior)

Storage: Wine vats (prevents iron contamination), refrigerated warehouses

Compliance: Meets FDA CFR 21, 3-A Sanitary Standards for surface roughness (Ra ≤ 0.8 μm)

4. Automotive & Transportation

Exhaust systems: Ferritic 409/439 (resists salt-induced corrosion)

Fuel cells: 316L bipolar plates (high acid resistance)

Rail: Maglev train tracks (non-magnetic 316N), subway car bodies

Emerging use: Hydrogen storage tanks (duplex steels for 700-bar pressure)

5. Energy Sector

Nuclear: Reactor coolant pipes (316NG with nitrogen strengthening)

Oil/Gas: Subsea Christmas trees (super duplex UNS S32750 for chloride resistance)

Renewables: Solar thermal collectors (ferritic 444), tidal turbine shafts

Extreme conditions: Withstands temperatures from -270°C (cryogenic 304) to 1150°C (310S alloy)

6. Chemical Processing

Reactors: Hastelloy C-276 clad vessels (for HCl environments)

Piping: Duplex 2205 for sulfuric acid transport

Valves: 17-4PH precipitation-hardened steel (combines corrosion resistance with 1300 MPa strength)

7. Water Treatment

Desalination: Super duplex pumps handling 35,000 ppm salinity

Wastewater: Aeration systems (resists H₂S-induced pitting)

Potable water: 304 storage tanks (meets NSF/ANSI 61 standards)

8. Aerospace

Engine components: 321 grade (Ti-stabilized for jet engine exhausts)

Fuel lines: 15-5PH for high strength-to-weight ratio

Space applications: Cryogenic 304L for liquid oxygen tanks

Specialized Grades & Innovations

Marine: 6Mo alloys (AL-6XN) for offshore rigs

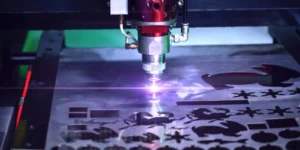

3D Printing: Gas-atomized 316L powder for AM parts

Sustainable: 60% recycled content in typical 304 alloy

Selection Factors

Corrosion: PREN >40 for seawater (PREN = %Cr + 3.3×%Mo + 16×%N)

Strength: Duplex grades offer 2x yield strength of 304

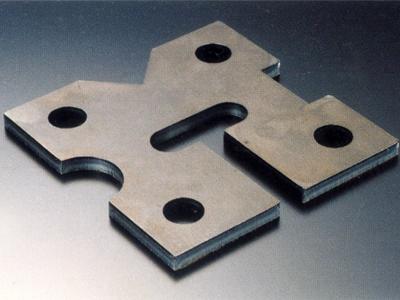

Fabrication: 430F improves machinability (0.15% S added)

Cost: 201 replaces 304 in some applications (Mn/N substitution)

This engineered material continues evolving with advances like nano-structured 316L (improving yield strength by 40%) and smart surface treatments (laser-clad antimicrobial copper-stainless composites). Its lifecycle cost benefits (50+ year service in architecture) ensure growing adoption as industries prioritize durability and sustainability.