Metal hardness (typically measured on scales like Rockwell C – HRC, or Vickers – HV) is a critical property determining a part’s suitability for specific applications. Here’s a breakdown of common hardness ranges and their ideal usage scenarios:

Low Hardness (e.g., Annealed Steels: < 20 HRC, Pure Copper/Aluminum: < 60 HV)

Typical Metals: Annealed low-carbon steels (1018, A36), annealed copper, annealed aluminum alloys (1100), lead, tin, some soft bronzes.

Key Properties: Excellent ductility, formability, machinability, ease of cold working (bending, drawing, stamping), good impact absorption, good electrical/thermal conductivity (for Cu/Al).

Ideal Application Scenarios:

Deep Drawing & Forming: Car body panels, cans, complex stamped components, sink bowls.

Electrical Conductors: Busbars, wire windings, electrical connectors (where high conductivity is paramount).

Sealing & Gasketing: Soft copper washers, crush gaskets, sealing foils.

Impact Absorption: Soft hammer heads (copper, lead), sacrificial anodes.

Machining Feedstock: Parts requiring extensive machining prior to potential hardening.

Decorative Forming: Easily shaped jewelry components or trim pieces.

Medium Hardness (e.g., Mild Steels: 20-35 HRC, Case-Hardened Surfaces: 50-60 HRC, Wrought Al Alloys: 60-100 HV)

Typical Metals: As-rolled mild steels (A500), normalized medium-carbon steels (1045), pre-hardened tool steels (O1, A2 at ~30 HRC), case-hardened low-carbon steels (1018, 8620 surface), harder aluminum alloys (6061-T6), brass, some bronzes.

Key Properties: Good balance of strength, toughness, and machinability. Better wear resistance than soft metals, while still offering reasonable ductility and formability. Case hardening provides a hard, wear-resistant surface over a tough core.

Ideal Application Scenarios:

General Structural Components: Frames, brackets, supports, axles, shafts (where moderate strength and good toughness are needed).

Machined Parts: Bolts, nuts, gears (especially before final hardening), hydraulic/pneumatic fittings.

Wear Components (Moderate Load): Bushings, lightly loaded gears, chain links, track rollers (often case-hardened for surface wear resistance).

Fasteners: Many standard bolts, nuts, and screws fall in this range.

Aerospace & Automotive Non-Critical: Brackets, housings, linkages made from aluminum alloys.

Consumer Goods: Hand tools (pliers, adjustable wrenches – bodies), appliance parts.

High Hardness (e.g., Quenched & Tempered Steels: 40-60 HRC, Tool Steels: 50-65 HRC)

Typical Metals: Quenched and tempered medium/high-carbon steels (4140, 4340, 5160), tool steels (D2, H13, M2), martensitic stainless steels (410, 440C), high-hardness cast irons.

Key Properties: High strength, excellent wear resistance, good resistance to plastic deformation (yield strength). Machinability decreases significantly; grinding is often required. Toughness can be lower than medium-hardness steels if not properly tempered.

Ideal Application Scenarios:

Cutting Tools: Drill bits, milling cutters, lathe tools, saw blades (HSS like M2).

High-Wear Components: Bearings (races/balls – 52100 steel ~60 HRC), gear teeth (hardened), wear plates, liners, extrusion dies.

High-Strength Structural Parts: Crankshafts, connecting rods, high-stress bolts, springs (music wire ~60 HRC), landing gear components.

Molds & Dies: Injection mold cavities/cores, die casting dies, forging dies (tool steels like H13, P20).

Knives & Blades: Chef’s knives, pocket knives, industrial blades (stainless like 440C or tool steels).

Very High / Ultra-High Hardness (e.g., Hardened Tool Steels: >60 HRC, Cemented Carbides: 70-90 HRC, Ceramics: >80 HRC)

Typical Metals: Maximally hardened tool steels (files ~65 HRC), high-speed steels (M42, M48), cemented carbides (tungsten carbide-cobalt), hard-facing alloys (Stellite), ceramics (SiN, AlO).

Key Properties: Extreme wear resistance, high compressive strength, excellent hot hardness (for HSS/carbides), very high resistance to abrasion and erosion. Extreme brittleness is a major limitation; impact resistance is very low. Machining is impossible; shaping requires grinding or EDM.

Ideal Application Scenarios:

Abrasive Wear Applications: Mining/earth-moving equipment teeth, crusher liners, slurry pump impellers/liners (often carbide inserts or hard-facing).

High-Performance Cutting Tools: Indexable carbide inserts for machining, saw tips for cutting concrete/stone, wire drawing dies.

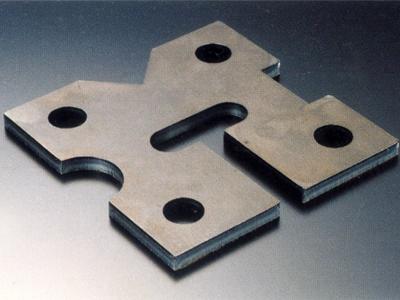

Metal Forming Tools: Deep drawing dies, fine blanking punches/dies (carbide).

Wear Surfaces (Severe): Guide rollers in steel mills, valve seats/seals in abrasive fluids (Stellite).

Precision Components: Gauge blocks, precision bearing components in specialized applications (ceramics).

Files & Rasps: Require maximum hardness for cutting softer metals.

Key Considerations:

Toughness vs. Hardness: Higher hardness usually means lower toughness (resistance to fracture). Applications subject to impact or shock loading need careful material selection (e.g., a hammer head needs toughness, a cutting edge needs hardness).

Core vs. Surface Hardness: Techniques like case hardening (carburizing, nitriding) or surface treatments (induction hardening) create a hard, wear-resistant surface while maintaining a tougher core. Ideal for gears, bearings, shafts.

Machinability: Softer metals are much easier and cheaper to machine. Hard parts (>45 HRC) often require grinding, increasing cost.

Corrosion Resistance: Hardness alone doesn’t confer corrosion resistance. Stainless steels offer a combination, but their maximum hardness is often lower than dedicated tool steels or carbides.

Application Environment: Temperature, corrosion, impact load, and the type of wear (abrasive, adhesive, erosive) are crucial factors alongside hardness.

Selecting the optimal hardness involves balancing wear resistance, strength, toughness, manufacturability, and cost for the specific demands of the application.