The laser engraving effect on aluminum material does not depend on the type of substrate, but rather on its surface finishing condition. Here are three kinds of aluminum with different surface treatments that are commonly used for laser engraving:

Anodized aluminum

Based on the anodizing process, the thickness of the anodized layer typically ranges from 5 ~ 60 μm, while the commonly used fiber laser engraving only reaches a depth of 0.2 – 1 μm.

Therefore, the laser doesn’t remove any base material, but only alters the aluminum oxide layer.

Typically, uncolored anodized aluminum produces dark gray markings, colored anodized aluminum produces black markings, both are clear and high-contrast.

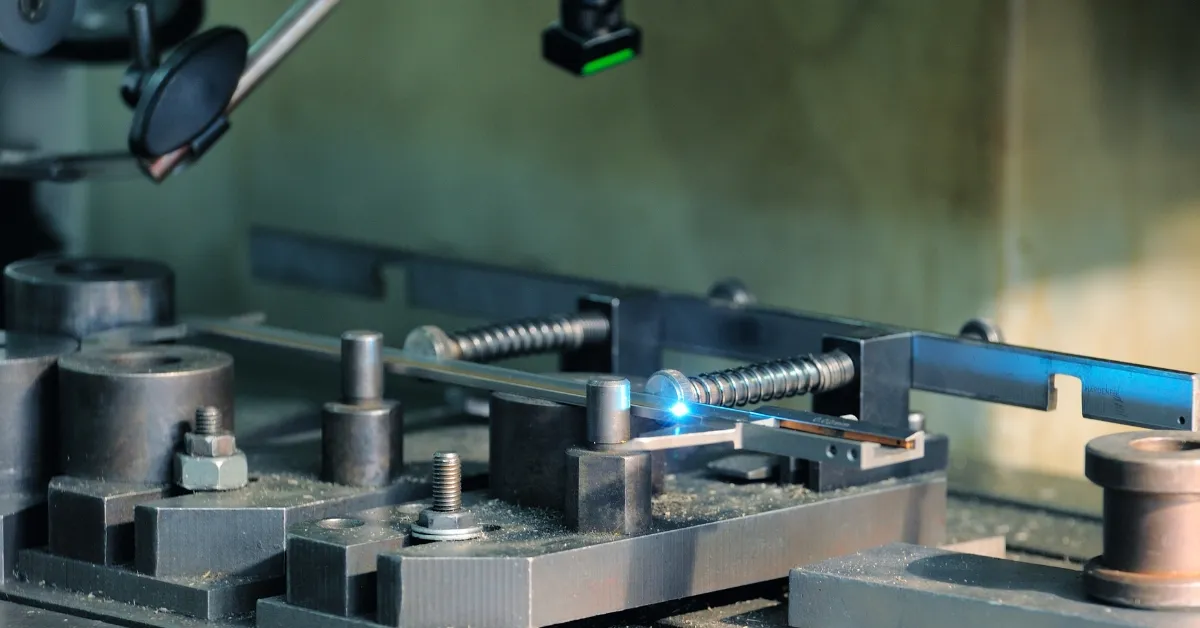

Bare Aluminum

Bare aluminum is natural aluminum without any surface treatment, making the cost relatively inexpensive. Laser melts bare aluminum and carves out patterns that have subtle contrast but are permanent.

It should be noted that due to aluminum’s low hardness and heat sensitivity, it is necessary to adjust the appropriate parameters and speed of laser engraving to control quality.

Powder-coated aluminum

Powder-coated aluminum is sprayed with plastic polymers (such as epoxy resin or polyester), allowing for various colors to be applied. Laser ablates and vaporizes the coating, exposing the underlying aluminum to create a contrasting pattern.

This offers a colorful appearance for designs, being cost-effective and environmentally friendly. However, the coating is not wear-resistant, which may affect the engraving quality.