CNC machining of brass has many advantages, which is why it is widely used in many industries. Here are the key benefits:

High Precision and Accuracy

CNC machines follow electronic plans with high levels of accuracy. This helps ensure the final output is correct and has gone through the standard checks to be accurate. This is the reason why brass parts can be manufactured to meet specific requirements time and again. It minimizes mistakes and increases the general quality of the products being manufactured. Reliability is an essential aspect of applications where the outcomes are significant. CNC machining also offers a method of sustaining small tolerances, which is necessary for most applications. Machining is very accurate, meaning the material’s performance and reliability are very high, and the tolerances are usually within ±0. 005 inches.

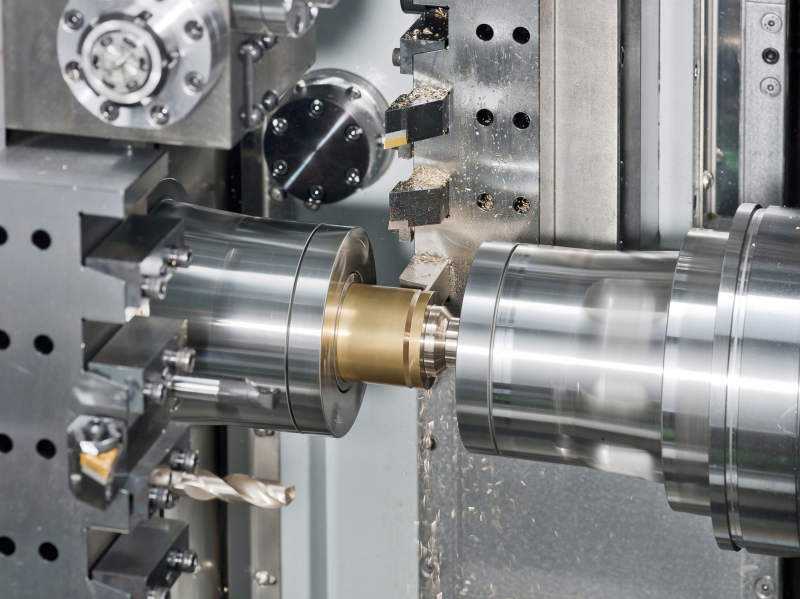

Exceptional Machinability

Brass is well known for its good machinability and ease of working, making it ideal for brass tooling. Complex parts can be produced with high precision and intricate features. This results in less time spent on the machines and, therefore, lower manufacturing costs. Another advantage of machining brass is that the tool life is also extended. Less wear and tear on tools means that the price is reduced. Moreover, brass has good machinability and enhances the manufacturing processes of products made from the material. High machinability allows for the creation of prototypes and fast production time with surface roughness ranging from Ra to 0.8 µm.

Corrosion Resistance

Brass is more resistant to corrosion in extreme conditions than any other material of a similar kind. This is good for areas with high humidity or where the item may come into contact with water. This durability is essential, especially in applications such as outdoor or marine environments. Brass is long-lasting, and products made from it do not degrade quickly. Brass is corrosion-resistant, which makes it durable and reliable. This property helps to minimize the amount of maintenance required, hence cutting down on costs that are likely to be incurred. Corrosion resistance also increases the life span of brass parts by many folds and can go up to more than 30 years in the right environment.

Versatility

The properties of Brass can be changed by changing the components of the material. This makes it possible to produce concentration alloys for specific applications. The material can be cut to fit the needs of various industries. This is why brass has been widely used in many fields, as it is very versatile. It is used in plumbing, electrical components, and other related applications. Depending on the grade of the brass, it will have a different level of strength and corrosion resistance. Versatility also enhances creativity in product design and use with tensile strengths of 350 MPa to 700 MPa.

Cost-Effectiveness

Brass CNC machining is relatively inexpensive and fast. It is possible to manufacture high-quality parts at a minimum cost. This makes it a good option for businesses that are operating under a tight budget. Reduced production costs do not affect the quality of the brass parts in any way. Efficiency contributes to the ability to set appropriate prices and achieve high profitability. Machining efficiency means that there is little wastage of material and that the material is used to the maximum possible extent. In general, brass cnc machining is very cost-effective, with the cost of the material ranging from $2 to $3 per pound.

Fast Production Times

CNC machines help in the fast and effective manufacturing of brass parts. Reduced lead times increase the general productivity of the business. Fast production is beneficial because it can meet the customer’s order faster. This speed is essential in satisfying the demand and the time the food has to be prepared. CNC machining is suitable for both small and large-volume production. Brass has good machinability, which favors rapid manufacturing processes. Short cycle times benefit businesses by allowing them to be more responsive and produce parts in hours rather than days.

Conductivity

Brass is electrically and thermally conducting material. This makes it ideal for heat or electricity transfer operations. It is commonly applied in electrical parts and heat exchangers. Conductivity leads to high performance in challenging technical applications. Conductivity is a parameter that is most important for the safety and functionality of the equipment. Brass is also characterized by good conductivity and relatively stable conductivity coefficients over a wide temperature range. This makes it suitable for multiple electrical and thermal applications, and its electrical conductivity is approximately 28% IACS (International Annealed Copper Standard).

Aesthetic Appeal

Brass has an inherent golden color with a shiny surface to it. It is preferred for ornamental applications and luxury goods. The material also has the aspect of beauty that makes people want to use it. Brass parts are used in applications that are considered luxurious and are supposed to be in the design category. Brass gives the product a nice finish, which makes the product more marketable. The look is still good, and little effort and attention are needed for maintenance. Beauty and utility go hand in hand, and they are used in items that require both looks and strength, such as musical instruments and architectural hardware.