What is aluminum a380 alloy?

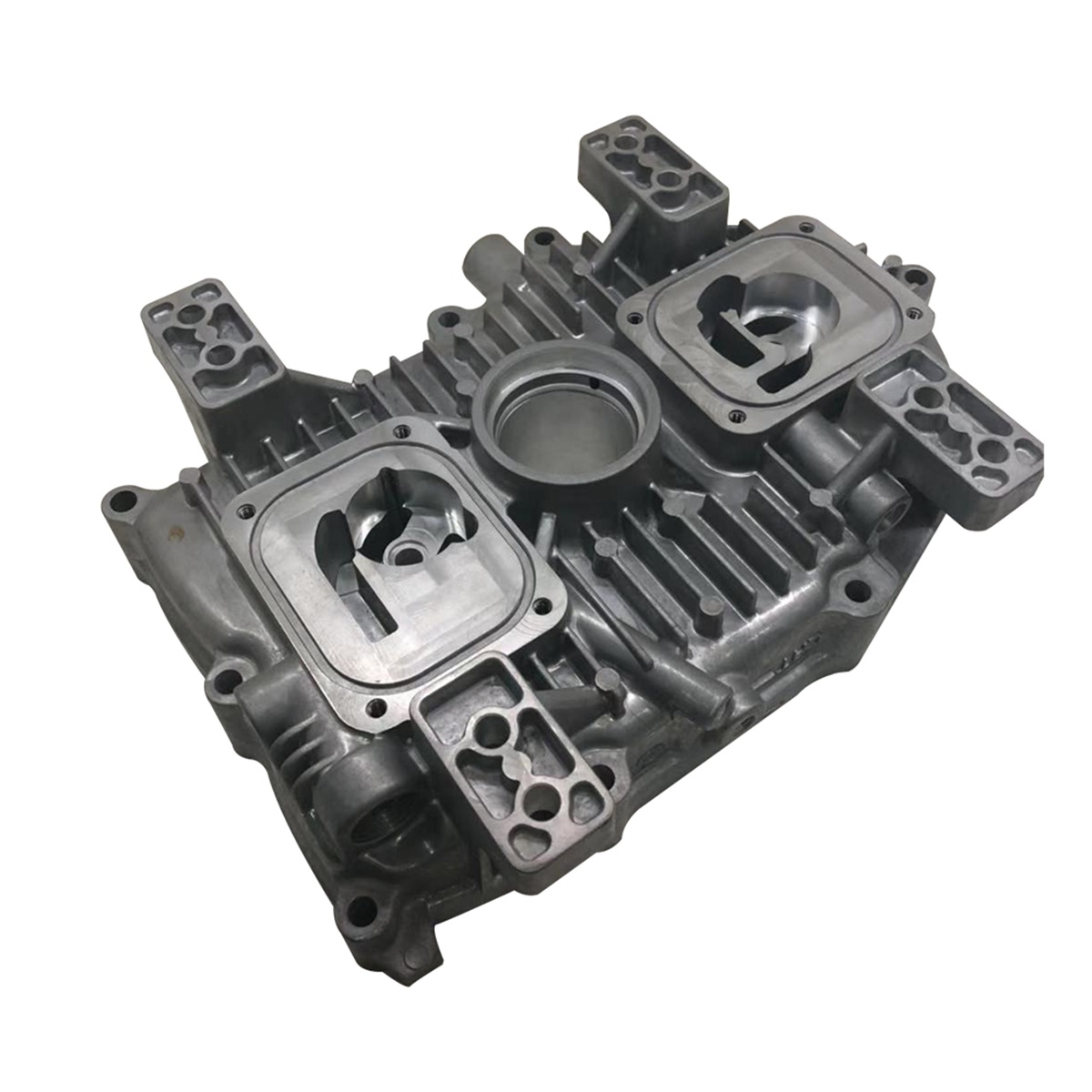

In die casting, aluminum A380 alloy helps make complex parts with high precision. It is primarily aluminum, with silicon (Si) for improved fluidity during casting. Other elements like copper (Cu) contribute to strength and other properties.

Aluminum A380 Standards

A380 aluminum is subject to different standards depending on the region and specific application, with:

ASTM International (ASTM): The ASTM B179 standard specification covers a380 aluminum alloy used in die casting. This standard identifies the chemical composition, mechanical properties, and other requirements for A380 in die casting applications.

Aluminum Association (AA): According to the Aluminum Association, AA380.0-F identifies A380 in the US. That name has the same meaning as ASTM B179.

International Organization for Standardization (ISO): ISO designation EN1706: AlSi9Cu3(Fe) may also mean A380 in Europe. This standard uses a slightly different notation to state the chemical composition of the alloy (AlSi9Cu3 means Aluminum 9% Silicon Copper 3% Iron).

Society of Automotive Engineers (SAE): SAE also provides a nomenclature for aluminum alloys. Within the automotive industry, “SAE 380” refers specifically to A380 sometimes.

Importance of Aluminum A380 Standards

The essence of Aluminum A380 standards concerns the necessity of having the suitable material for your particular use and meeting any such industry requirements. Here is why standards matter:

Consistent Composition and Properties: Standards determine the actual chemical composition of A380 and its mechanical properties, such as tensile strength and elongation, which means you get a material with predictable performance. Deflection from this standard may lead to unexpected results in the final product.

Quality Control: Standards often provide guidelines on quality control procedures that manufacturers must adhere to during the production process; as a result, these ensure that what you have been given meets the specific demands of the individual concerned.

Traceability: Maintaining traceability within certain establishments that require strict quality controls is vital.

Industry Acceptance: Specific industries like automotive or aerospace have material selection criteria. These guidelines often refer to recognized standards on A380 to ensure compatibility and performance within their applications.

Avoiding Issues: There could be several problems arising from using unsuitable grades of A380:

Performance Issues: The end product may not have expected strengths, resistance against corrosion, or similar attributes.

Safety Concerns: In critical applications, wrong A380 selections may create safety risks due to possible failures.

Production Delays: Failure of the material to meet specifications will cause delays and rework costs.