In the age of Industry 4.0, the most advanced manufacturing is defined not only by machinery but by data intelligence. The true mark of a modern supplier lies in the ability to connect every stage of production into a seamless, transparent, and optimized digital flow. At Juize Machinery, we are integrating smart manufacturing principles into our core operations, enhancing our multi-process capabilities with a digital thread that ensures unparalleled precision, traceability, and proactive quality assurance. As your Gold Verified Supplier on Alibaba, we are committed to leveraging technology not as a buzzword, but as a tangible tool to deliver superior reliability and insight for your projects.

Beyond the Machine: The Power of Connected Manufacturing

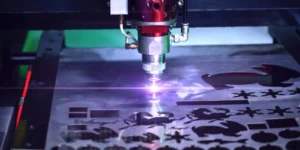

Smart manufacturing moves us from reactive correction to predictive control. By embedding sensors, utilizing IoT platforms, and implementing digital workflows, we create a cohesive ecosystem where data informs decision-making at every step—from material reception to final shipment.

Key Pillars of Our Smart Manufacturing Approach

Digital Process Management & Paperless Workflow

Every order is managed through a centralized digital system, ensuring that specifications, drawings, and revisions are instantly accessible across production, quality, and logistics teams.

This eliminates errors from outdated paper drawings, accelerates change order implementation, and provides you with a real-time portal for project status updates.

In-Process Monitoring & Data Analytics

Critical machinery is equipped with monitoring systems that track parameters like vibration, temperature, and tool wear in real-time. This allows for predictive maintenance, preventing unplanned downtime and ensuring consistent part quality.

For high-volume runs, Statistical Process Control (SPC) data is collected automatically, enabling our engineers to detect and address process variations before they lead to non-conforming parts.

The Digital Twin & Advanced Quality Planning

For complex components, we utilize 3D models as “digital twins” to simulate manufacturing processes, predict potential issues like tool interference or material stress, and optimize CNC programming offline, reducing setup time and material waste.

First Article Inspection (FAI) reports are generated digitally, often with automated data collection from CMMs, ensuring speed and absolute accuracy in validating that the first part conforms perfectly to your 3D model and GD&T callouts.

End-to-End Digital Traceability

Each component or batch is assigned a unique digital identifier. This allows us—and you—to trace its full history: material certifications, heat treatment logs, machining parameters, inspection results, and shipping details.

This comprehensive digital dossier is invaluable for quality audits, root cause analysis, and meeting stringent regulatory requirements in industries like aerospace, medical, and automotive.

How This Digital Advantage Translates to Your Benefit

Enhanced Precision & Consistency: Data-driven process control minimizes human error and variability, delivering parts with repeatable, certified accuracy.

Proactive Risk Mitigation: We can identify and communicate potential delays or quality concerns early, based on data trends rather than guesswork.

Informed Collaboration: We can share relevant process data and quality metrics, providing you with deeper insight into your component’s manufacturing journey and enabling collaborative continuous improvement.

Future-Proofed Partnership: Investing in this digital infrastructure ensures we remain a capable, efficient, and transparent partner as product lifecycles shorten and complexity grows.

Smart Manufacturing, Powered by Human Expertise

Our technology serves to augment, not replace, the deep manufacturing expertise of our engineers and technicians. The “smart” in our system is the synergy between advanced digital tools and decades of hands-on process knowledge in casting, forging, machining, and finishing.

Ready to partner with a manufacturer that combines traditional craftsmanship with digital precision?

Discover how our smart manufacturing and integrated digital traceability can bring a new level of confidence and control to your supply chain.

Contact us to learn more about our digital capabilities and request a sample of our digital quality documentation.

www.juizemachinery.com

—

Where Precision Meets Intelligence.

The Juize Machinery Team