The journey toward a reliable and cost-effective custom part begins with a critical, yet often challenging, decision: material selection. This choice fundamentally dictates the component’s performance, manufacturability, lifespan, and total cost. At Juize Machinery, we recognize that our expertise extends beyond shaping metal—it encompasses guiding our partners through the complex landscape of material science. As a Gold Verified Supplier on Alibaba, we provide more than manufacturing; we offer informed, application-driven material consultancy to ensure your design is built on the optimal foundation.

Why Material Choice Matters More Than Ever

Selecting the wrong alloy can lead to premature failure, unnecessary cost, or production difficulties. The ideal material achieves a precise balance between:

Mechanical Properties: Strength, hardness, toughness, and fatigue resistance.

Physical Characteristics: Weight, thermal & electrical conductivity, and magnetic properties.

Environmental Resistance: Corrosion, wear, and temperature tolerance.

Manufacturability: How easily it can be cast, forged, machined, or formed.

Total Cost: Including raw material price, processing costs, and part lifecycle value.

Our Consultative Approach to Material Specification

We move beyond simply accepting a material callout on a drawing. Our engineers engage in a collaborative review process to validate or recommend the best option:

Application Analysis: We start by understanding the part’s function, load conditions, operating environment (exposure to chemicals, temperature extremes, etc.), and required lifespan.

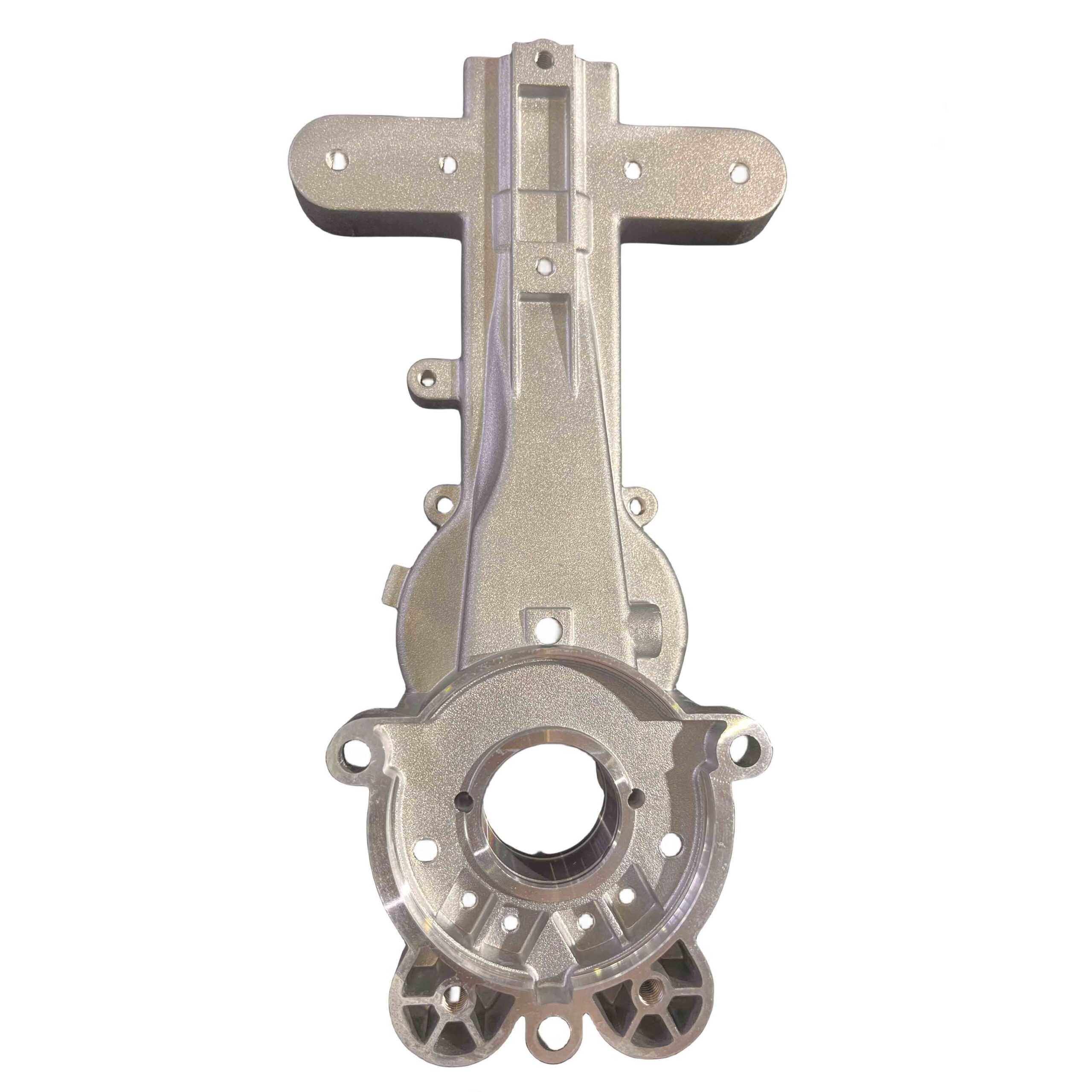

Process-Material Synergy: We evaluate how the chosen manufacturing process interacts with the material. For instance, a grade of aluminum ideal for extrusion may differ from one best suited for high-integrity casting or CNC machining. Our multi-process expertise allows us to recommend the optimal alloy for the chosen fabrication method.

Comparative Evaluation & Cost-Benefit Modeling: We often present data-driven alternatives. Could a high-strength aluminum replace a more expensive stainless steel with a slight design adjustment? Would a powdered metal alloy offer a better solution for a complex, low-weight gear? We clarify the trade-offs between performance, manufacturability, and cost.

Supply Chain & Availability Insight: Leveraging our Gold Supplier network, we provide realistic guidance on material availability, lead times, and strategic sourcing options to mitigate supply chain risk for your project.

Deep Knowledge Across Key Material Families

Our experience spans a wide spectrum of metals and alloys, allowing for unbiased guidance:

Steels & Alloy Steels: From low-carbon steels for general fabrication to hardened alloy steels for gears and shafts, with knowledge of pertinent heat treatments.

Stainless Steels: Guidance on the nuances between austenitic (304, 316), martensitic (410, 440), and duplex grades for varying corrosion and strength needs.

Aluminum Alloys: Expertise in die-casting alloys (A380, A360), extrusion grades (6061, 6063), and high-strength machinable alloys (7075).

Copper & Brass Alloys: For applications requiring superior conductivity or specific aesthetic and corrosion properties.

Specialty Alloys & Powder Metallurgy Materials: Including titanium, Inconel®, and custom powder blends for unique applications.

From Recommendation to Verified Reality

Our material guidance is backed by our integrated verification system. Once selected, we ensure material integrity through certified sourcing, incoming material testing (like spectrometry), and process controls that protect the material’s properties through every production stage.

Uncertain about the best material for your next component?

Leverage our engineering partnership. Contact us for a complimentary design-for-manufacturability review, including material optimization analysis.

Partner with us to build your product on the right foundation.

www.juizemachinery.com

Expertly Selected. Precisely Made.

The Juize Machinery Team