Solution Heat Treatment, often simply called solutionizing or solution annealing, is a critical thermal processing operation primarily applied to non-ferrous alloys, most notably aluminum alloys, precipitation-hardening (PH) stainless steels, and some nickel-based superalloys. Its primary purpose is to dissolve alloying elements into a solid solution within the base metal matrix, creating a supersaturated state that is a prerequisite for subsequent age hardening (precipitation hardening).

1. The Fundamental Objective

The core goal is to produce a homogeneous, single-phase solid solution at an elevated temperature and then to “freeze” this state by rapid cooling (quenching). In many alloys, alloying elements have limited solubility in the base metal at room temperature, forming secondary phases or precipitates. Solution treatment aims to dissolve these precipitates back into the matrix.

2. The Three-Step Process

The process consists of three distinct and crucial stages:

- Heating (Soaking)

The alloy is heated to a specific, carefully controlled temperature, known as the solution heat treatment temperature. This temperature is high enough to:

Dissolve the soluble alloying elements and secondary phases (e.g., CuAl₂ in aluminum-copper alloys) completely into the base metal.

Achieve a chemically homogeneous, single-phase solid solution (e.g., austenite in PH steels or alpha-aluminum in Al-alloys).

The component is held at this temperature for a sufficient duration, known as the soaking time, to ensure complete dissolution and homogenization. The time depends on the part’s thickness and the alloy’s composition.

- Rapid Quenching

This is the most critical step. The component is rapidly cooled from the solution temperature to room temperature.

The quenching medium (typically water, but also oil, polymer solutions, or air for less sensitive alloys) must be fast enough to prevent the dissolved elements from diffusing out of the solution and forming coarse precipitates.

The result is a metastable, supersaturated solid solution (SSSS). The atoms of the alloying elements are trapped within the crystal lattice of the base metal, creating a state of high internal strain. This structure is not at equilibrium; it is inherently unstable but provides the necessary condition for the next stage.

- Aging (Precipitation Hardening) – The Follow-up Step

The as-quenched material from solution treatment is typically soft, ductile, and has high internal stress. It is not yet in its final, high-strength condition.

The supersaturated solid solution is then heated to a lower temperature (the aging temperature) and held for a specific time.

During aging, the supersaturated elements precipitate out in a fine, dispersed form throughout the matrix. These finely distributed particles act as obstacles to dislocation movement, dramatically increasing the strength, hardness, and yield strength of the alloy. This entire two-step sequence is known as Precipitation Hardening or Age Hardening.

Solution Treatment + Quenching + Aging = Precipitation Hardening

3. Key Parameters and Metallurgical Mechanisms

Temperature Control: Precise control is vital. If the temperature is too low, incomplete dissolution occurs. If it’s too high, it can cause localized melting (eutectic melting) at grain boundaries, leading to a catastrophic loss of mechanical properties.

Quench Rate Sensitivity: The speed of quenching is paramount. A slow quench allows time for coarse, equilibrium precipitates to form at grain boundaries. These are detrimental to both strength and corrosion resistance (especially in aluminum alloys, known as sensitization). However, a very fast quench can introduce significant residual stresses and cause distortion or warping of the component.

Metallurgical Changes: The process refines the microstructure by dissolving coarse, brittle intermetallic compounds. The subsequent aging treatment creates a uniform dispersion of nanoscale strengthening precipitates (e.g., Guinier-Preston zones, θ”, θ’ phases in Al-Cu alloys).

4. Practical Applications

Solution treatment is a foundational step for a wide range of high-performance components:

Aerospace: Aircraft wings, fuselage skins (from 2xxx and 7xxx series aluminum alloys).

Automotive: High-strength suspension components, wheels, and engine parts.

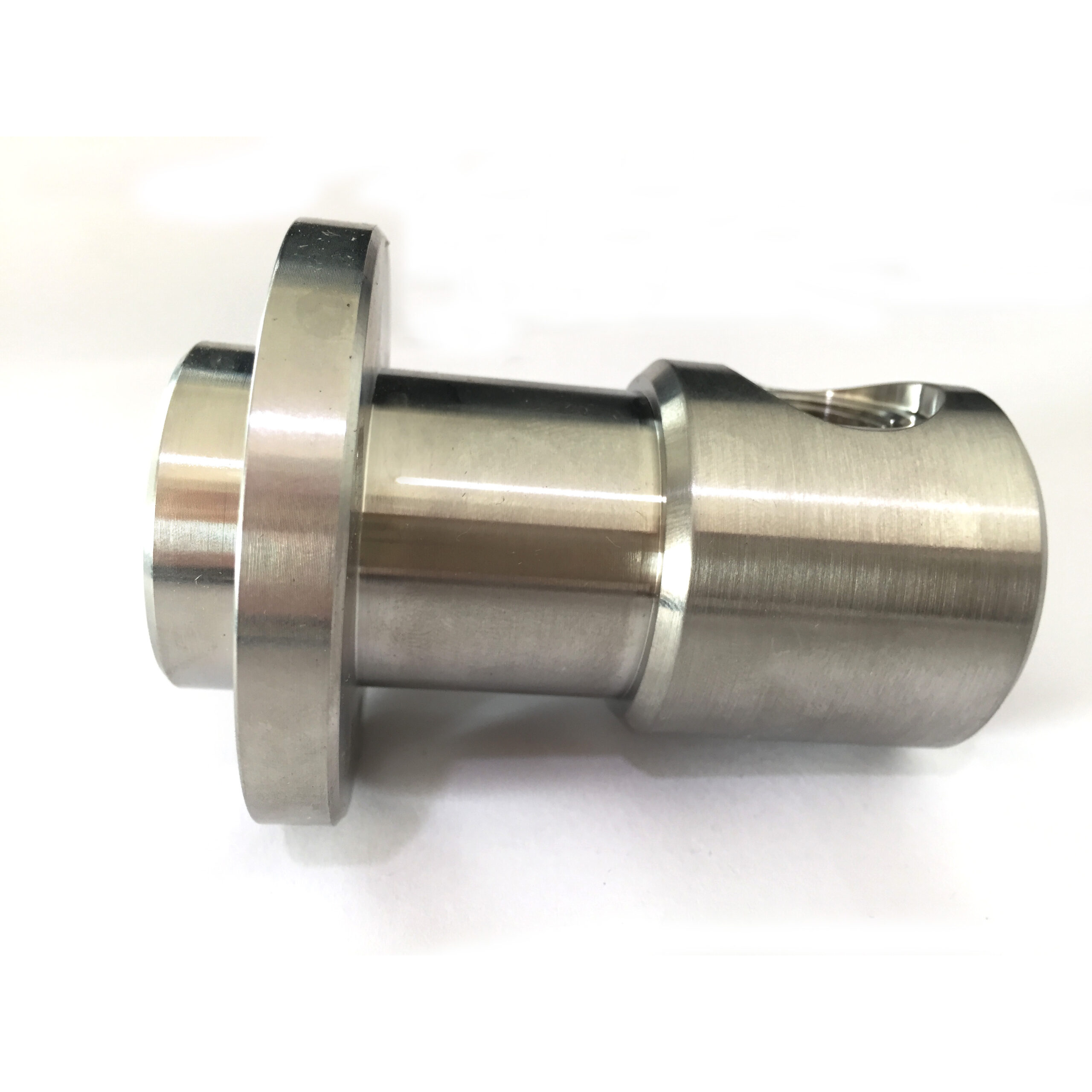

Marine and Chemical Processing: Pump shafts, valves, and fittings made from precipitation-hardening stainless steels (e.g., 17-4 PH, 15-5 PH).

Sporting Goods: High-performance bicycle frames, baseball bats, and rock-climbing equipment.

Summary

In essence, solution heat treatment is the first and essential step in the precipitation hardening process. It creates a uniform, supersaturated solid solution by dissolving soluble phases at high temperature and “freezing” them in place via rapid quenching. This prepared microstructure is then transformed in the subsequent aging treatment to develop the high strength-to-weight ratio and mechanical properties that make these alloys indispensable in advanced engineering applications.