Aerospace & Aviation

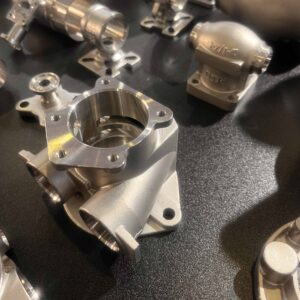

The aerospace industry pushes the limits of materials and precision, requiring components that are incredibly lightweight, strong, and reliable.

Lightweight Structural Components: Parts like titanium alloy engine mounts and airframe brackets are often custom-machined to achieve optimal strength-to-weight ratios. Companies develop custom “high-strength, low-temperature resistant” connection pins for critical applications, such as those used in European trains.

Engine and Turbine Parts: Components such as turbine blades and fuel nozzles feature intricate internal cooling channels. These complex geometries are increasingly produced using custom 3D printing (Additive Manufacturing) with high-performance superalloys.

Satellite and UAV Components: Custom-made antenna brackets and waveguides are designed to fit the extreme constraints of satellites and drones, ensuring performance under intense vibration and thermal cycles.

New Energy Vehicles (NEVs)

The shift to electric and smarter vehicles creates unique demands for performance, safety, and customization.

Battery System Components: Customization is critical for safety and efficiency. This includes custom battery pack enclosures, high-strength blind rivet systems for secure cell mounting, and cooling plate manifolds. Custom-engineered materials, such as halogen-free flame-retardant PC/ABS alloys, are developed specifically for battery components to meet automotive safety and environmental standards.

Power Electronics Housings: Housings for inverters and motor controllers require custom designs for efficient heat dissipation, electromagnetic shielding, and precise mounting of internal parts.

Lightweight Body and Interior Parts: To extend driving range, automakers use custom 3D-printed brackets and interior components like center console armrests. For example, a 3D-printed center console bracket can be produced as a single, complex part that is 20% lighter than its traditionally manufactured counterpart.

Medical Devices & Implants

Personalized healthcare is a major driver for custom machining, moving towards solutions tailored to individual patients.

Surgical Guides and Instruments: Surgeons use patient-specific surgical guides and custom-shaped tools designed from a patient’s CT or MRI scan data. These are often 3D printed to ensure perfect fit and improve surgical outcomes.

Orthopedic and Dental Implants: Items like spinal cages and dental implants are increasingly custom-made. Additive manufacturing allows for the creation of implants with porous surface structures that promote better bone ingrowth and integration compared to standard implants.

Robotics & Advanced Machinery

Robotics, from industrial automation to collaborative robots (cobots), requires highly specialized components.

Robotic Arm Components: Custom actuator housings, precision gearboxes, and sensor mounts are machined to tight tolerances to ensure smooth, accurate, and reliable movement.

End-of-Arm Tooling (EOAT): Grippers and specialized tools attached to a robot’s arm are frequently custom-designed to handle specific parts or perform unique tasks in assembly and packaging lines.

High-Performance Joint Parts: The industry has a pressing need for custom parts that act as the “arms or joints” of intelligent robots, which demand high precision and durability.

Consumer Electronics

The drive for thinner, lighter, and more powerful devices makes custom parts essential.

Heat Sinks and Spreaders: As devices become more powerful, managing heat is crucial. Custom machined heat sinks with complex fin structures are designed for maximum thermal dissipation in confined spaces like smartphones and laptops.

Internal Brackets and Housings: Custom CNC-machined aluminum frames and thin-walled polymer housings provide structural integrity and precise fit for internal components like cameras and circuit boards.

Advanced Industrial Equipment

Semiconductor Manufacturing Tools: Parts for equipment like plasma etchers and deposition systems must be made from specialized materials that resist corrosion and maintain purity in harsh environments.

A Summary of Custom Parts in New Industries

Industry/Application Examples of Custom Parts Key Drivers for Customization

Aerospace & Aviation Engine mounts , Turbine blades , Satellite brackets Lightweighting, High Strength, Heat Resistance

New Energy Vehicles (NEVs) Battery pack components , Power electronics housings , Lightweight brackets Safety, Thermal Management, Range Extension

Medical Devices Surgical guides , Patient-specific implants Personalized Healthcare, Biocompatibility, Osseointegration

Robotics Actuator housings, Precision gears, Custom grippers Precision, Durability, Task-Specific Function

Consumer Electronics Advanced heat sinks, Internal structural brackets Miniaturization, Thermal Management, Aesthetics

In summary, the core driver across all these new industries is the need for optimized performance that standard parts cannot provide. Custom manufacturing, through advanced processes like CNC machining and Additive Manufacturing, enables the creation of complex, lightweight, and high-strength components that are fundamental to innovation. This shift is transforming manufacturers from simple part producers into vital solution providers.