According to the different media that generate lasers and the laser wavelengths, there are many types of aluminum laser engraving machines. Choosing the correct type of laser is crucial for the effect of aluminum engraving.

Fiber laser

Fiber laser has a wavelength of 1064nm, which can reach an absorption rate of about 4–10% by aluminum, making it ideal for engraving on all types of aluminum.

If you need large-scale, high-quality and detailed laser engraving on aluminum, a fiber laser engraver is the best choice.

CO₂ laser

CO₂ lasers (10.6µm wavelength) generate laser light using carbon dioxide gas. Due to the low absorption rate for bare aluminum, they are more suitable for aluminum that has undergone surface treatments (such as anodizing and powder coating).

CO₂ laser engraving can maintain the integrity of the material, but because it requires low speed and high power settings, its run time and cost are relatively high.

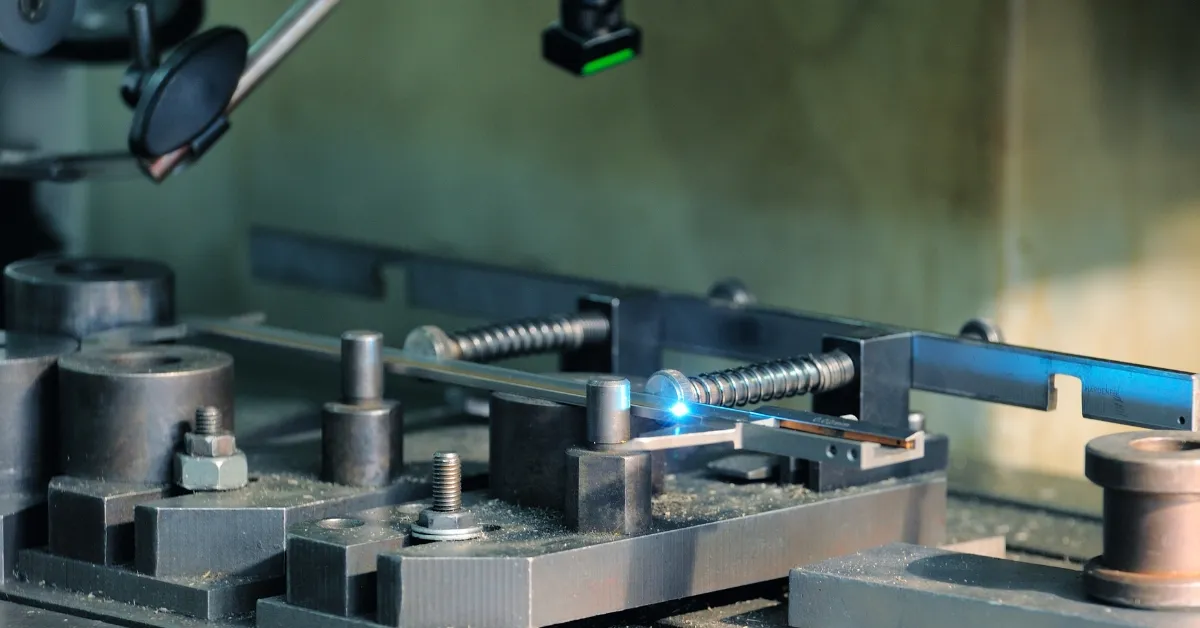

Diode laser

A diode laser is generated by a semiconductor diode, with wavelengths ranging from 450nm to 900nm. It is mainly used for anodized aluminum and powder-coated aluminum.

Due to their slower engraving speed and limited depth capability, diode lasers are only suitable for small batch design projects with shallow engraving depths.