Here’s a comprehensive overview of major welding methods, presented entirely:

- Fusion Welding (Melts Base Metals & Filler)

Arc Welding (Uses Electric Arc):

Shielded Metal Arc Welding (SMAW) / “Stick Welding”:

Process: An electric arc forms between a consumable electrode (stick) coated in flux and the workpiece. The heat melts the electrode tip and base metal, forming the weld pool. The flux coating vaporizes, creating shielding gas and forming slag.

Key Features: Portable, versatile (all positions, most metals), works outdoors/windy/dirty conditions, lower cost equipment. Slag removal required.

Gas Tungsten Arc Welding (GTAW) / “TIG Welding” (Tungsten Inert Gas):

Process: A non-consumable tungsten electrode creates the arc. Inert shielding gas (Ar, He, or mix) protects the weld area. Filler metal is added manually if needed. No slag.

Key Features: High precision, excellent weld quality & appearance, clean welds (no spatter/slag), welds almost any metal. Requires high skill, slower than MIG/FCAW.

Gas Metal Arc Welding (GMAW) / “MIG Welding” (Metal Inert Gas):

Process: A continuously fed consumable wire electrode creates the arc. Inert or active shielding gas protects the weld pool. No slag.

Key Features: Fast deposition rate, relatively easy to learn, good for thin/thick sections, minimal cleanup. Sensitive to wind/draft, requires gas supply.

Flux-Cored Arc Welding (FCAW):

Process: Similar to GMAW but uses a tubular wire filled with flux. Can use external shielding gas (“dual shield”) or rely solely on flux gas/slag (“self-shielded”).

Key Features: High deposition rate, deep penetration (especially dual-shield), good for thicker materials & outdoors (self-shielded), tolerates some contamination. Slag removal required, potential for more fumes.

Submerged Arc Welding (SAW):

Process: A continuously fed consumable bare wire electrode creates an arc under a blanket of granular fusible flux. The flux submerges the arc and molten pool, preventing spatter, arc glare, and fumes. Forms slag crust.

Key Features: Very high deposition rates, deep penetration, excellent quality for long straight/rotational seams (heavy plates, pipes, vessels). Limited to flat/horizontal positions, requires slag removal, high heat input.

Gas Welding / Oxy-Fuel Welding (OFW):

Process: Primarily Oxy-Acetylene Welding (OAW). Combines fuel gas (acetylene most common) and oxygen to produce a high-temperature flame. Melts the base metal edges and a filler rod is added.

Key Features: Portable, versatile (welding, brazing, cutting, heating), no electricity needed. Slower than arc welding, high heat input causes distortion, lower penetration compared to arc.

Energy Beam Welding:

Electron Beam Welding (EBW):

Process: A focused beam of high-velocity electrons in a vacuum chamber generates intense heat upon striking the workpiece.

Key Features: Extremely deep, narrow welds; minimal distortion/HAZ; high precision; welds refractory/reactive metals. Very high equipment cost, requires vacuum, precise joint fit-up.

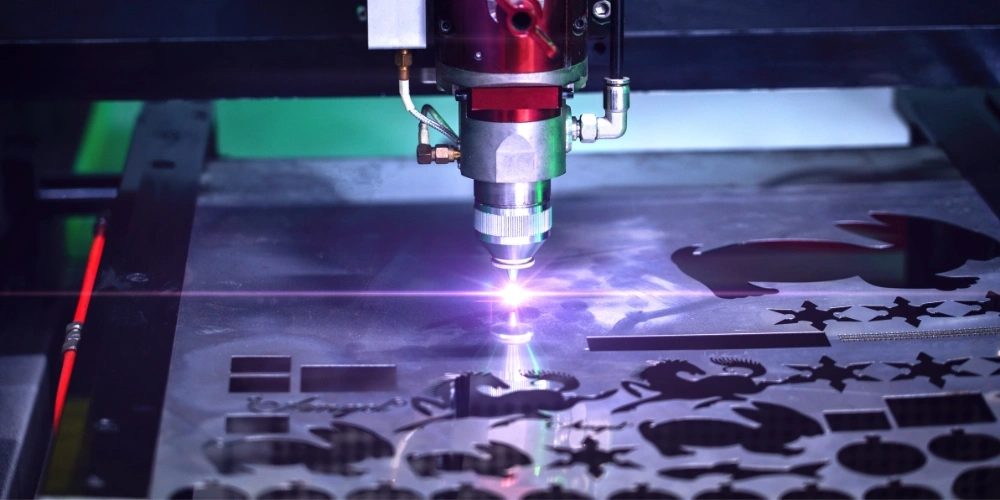

Laser Beam Welding (LBW):

Process: A highly focused laser beam melts the material. Can be done in air or with shielding gas.

Key Features: High speed, deep penetration possible, minimal distortion/HAZ, high precision, automatable. High equipment cost, sensitive to joint fit-up and reflectivity.

- Resistance Welding (Uses Heat from Resistance & Pressure)

Process: Heat is generated by passing a strong electrical current through the resistance at the joint interface of overlapping sheets/parts. Simultaneous pressure forges the heated parts together.

Major Types:

Resistance Spot Welding (RSW): Creates discrete weld “spots” between electrodes. Ubiquitous in automotive/aerospace sheet metal.

Resistance Seam Welding (RSEW): Creates a continuous leak-tight seam using rotating wheel electrodes.

Projection Welding (PW): Uses pre-formed projections (dimples, bumps) on one part to localize heat and pressure.

Key Features: Very fast, automatable (robots), no filler/shielding gas needed. Limited to lap joints on thin sheets, high initial equipment cost, requires access to both sides.

III. Solid-State Welding (No Bulk Melting of Base Metals)

Process: Joins materials using pressure (sometimes with heat below melting point) causing atomic diffusion or plastic deformation.

Major Types:

Friction Welding (FRW): Includes:

Rotary Friction Welding: One part rotates rapidly against a stationary part under axial pressure, generating friction heat. Rotation stops, forging pressure applied.

Friction Stir Welding (FSW): A rotating, non-consumable tool with a specially designed pin and shoulder is plunged into the joint line. Frictional heat softens the material, and the tool traverses along the joint, mechanically stirring the plasticized material to form the weld.

Forge Welding (FOW): Ancient method; heating metal to near-melt in a forge, then hammering together. Modern versions exist for chain making.

Explosive Welding (EXW): Uses controlled detonation to force one metal plate against another at high velocity/angle, creating a metallurgical bond at the interface.

Diffusion Welding (DFW): Parts held together under high pressure and elevated temperature for a prolonged time, allowing atoms to diffuse across the interface. Often done in a vacuum or inert atmosphere.

Ultrasonic Welding (USW): High-frequency ultrasonic vibrations are applied under pressure, causing localized plastic deformation and friction at the interface, primarily for thin sheets/foils and dissimilar metals (especially electronics).

Key Features: Often avoids HAZ issues & melting-related defects; can join dissimilar metals; FSW excellent for high-strength aluminum alloys. Processes often require specialized equipment/jigging, may have geometric limitations.

Key Factors Influencing Welding Method Selection:

Material Type & Thickness: Compatibility, conductivity, melting point.

Joint Design & Position: Butt, lap, fillet; flat, horizontal, vertical, overhead.

Required Weld Properties: Strength, ductility, toughness, corrosion resistance, leak tightness, appearance.

Production Requirements: Speed, volume, automation level, cost (equipment, consumables, labor).

Operating Environment: Shop, field, presence of wind/draft.

Operator Skill Level: GTAW requires high skill; GMAW/FCAW/SMAW are more accessible.

Post-Weld Requirements: Cleanup (slag removal), heat treatment, inspection level.

Available Equipment & Resources: Power source, gas supply, specialized machinery.

This overview covers the primary welding methods and their fundamental characteristics. Each process has numerous variations and applications tailored to specific industrial needs.