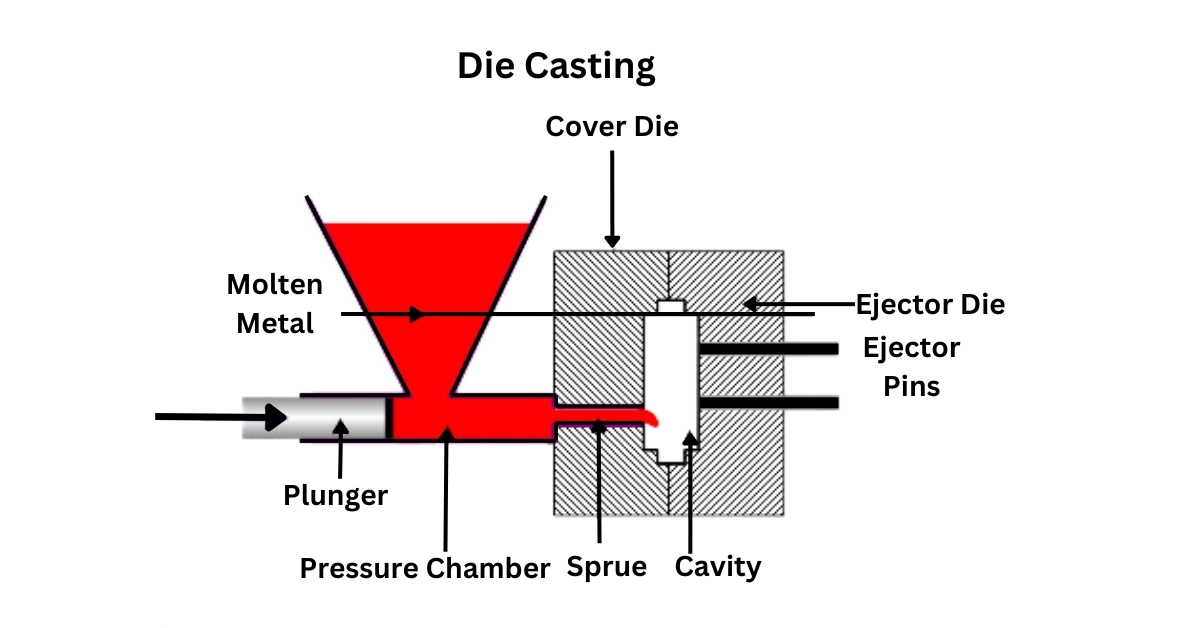

Die casting is a dynamic casting process where molten metal is injected under high pressure into a precision-engineered mold, known commonly as a die. This process starts with the preparation of the metal, usually aluminum or zinc alloys, which are melted in a furnace until they reach a liquid state.

Once the metal is molten, it is rapidly injected into the die using a hydraulic or mechanical piston. Pressure is maintained until the metal solidifies, capturing intricate details and ensuring structural integrity. The die is then opened to eject the casting and is quickly closed for the next cycle. This fast-paced method allows for a high production rate of complex metal parts with excellent surface finish and dimensional accuracy.