Here are the primary methods for detecting and verifying the magnetic field in Magnetic Particle Testing (MT) equipment, as per industry standards (e.g., ASTM E1444/E1444M, ISO 9934):

Tangential Field Strength Measurement (Direct Measurement):

Tool: Tangential Field Probe (Teslameter/Gaussmeter) with a Hall-effect sensor.

Method: Place the sensor probe perpendicularly (tangentially) on the part’s surface in the area of interest. Measure the component of the magnetic field parallel to the surface.

Purpose: Quantifies the actual magnetic flux density (B) at the surface. This is the most direct and quantitative method.

Requirements:

Central Conductor Technique: Minimum 2.4 kA/m (30 G) for prod/direct contact; 1.0 kA/m (12.5 G) for yoke techniques (ASTM E1444).

Overall Magnetization: Minimum 1.4 kA/m (17.5 G) on the surface (ISO 9934-1).

Advantages: Direct numerical value, reliable.

Limitations: Sensor positioning is critical; measures only the point under the probe; requires a calibrated meter; may not be practical for complex geometries.

Particle Performance / Artificial Flaw Indicators (Indirect Verification):

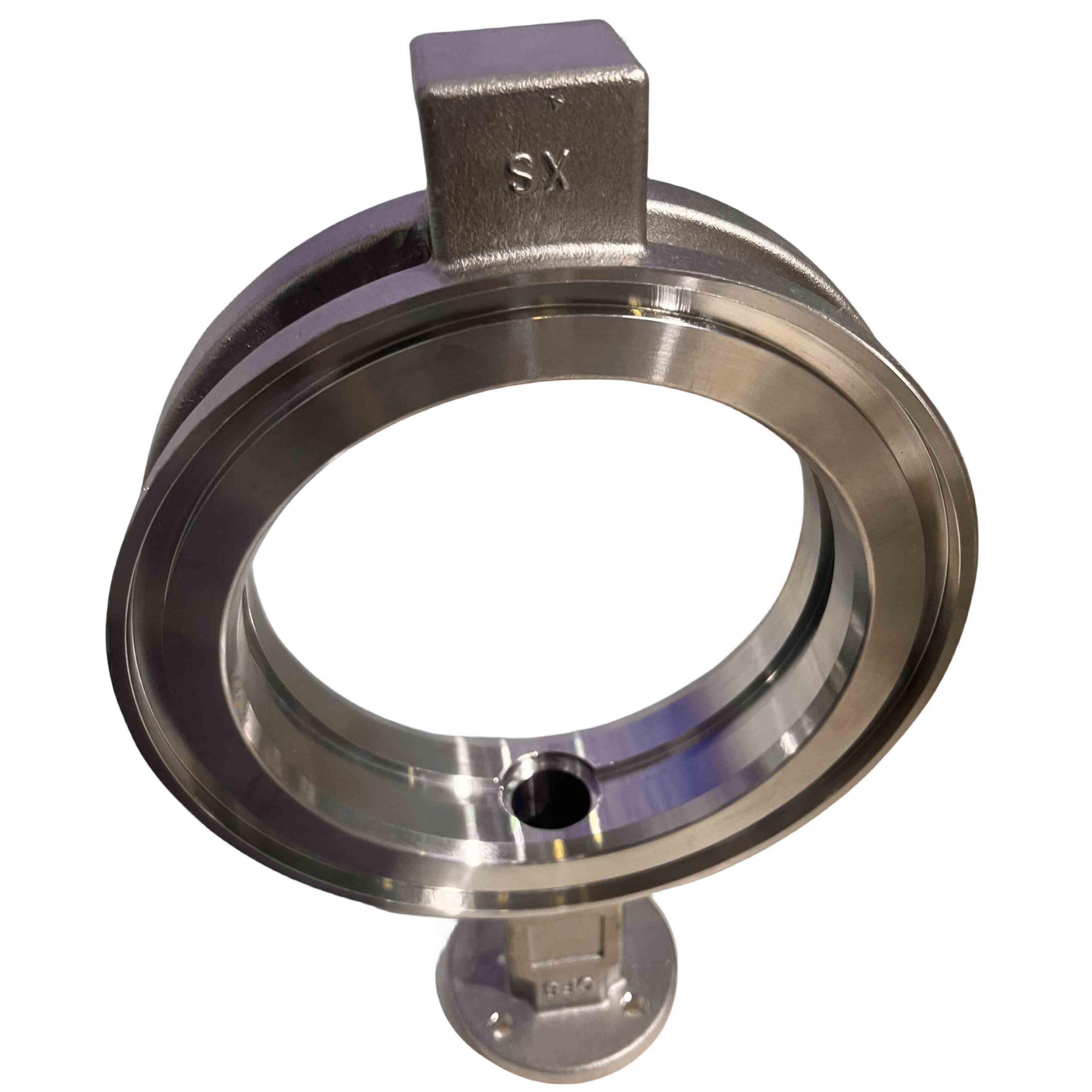

Tools: Pie Gauge (Qualitative), Ketos Ring (Quantitative), Shim stock with slots/notches, Casting with known flaws.

Method:

Pie Gauge: Place the gauge on the part. Apply particles during magnetization. Observe distinct particle buildup on the copper spokes. The number of spokes showing indications indicates field adequacy and direction.

Ketos Ring: Place the ring on or near the part. Apply particles during magnetization. The number of holes (or slots) showing distinct indications indicates relative field strength (e.g., 4 holes indicate sufficient field for most applications).

Shims/Flaws: Place a thin shim with artificial cracks (EDM slots, etched lines) or a reference specimen with known discontinuities on the part. Apply particles. Clear, sharp indications over the artificial flaws verify detection sensitivity and field adequacy/direction.

Purpose: Verifies the ability of the magnetic field and particle application process combined to detect relevant discontinuities. Confirms field direction.

Advantages: Practical, visual confirmation of system performance relative to detection sensitivity. Pie gauge clearly shows field direction.

Limitations: Qualitative (Pie) or semi-quantitative (Ketos). Results depend on particle quality, application technique, and lighting. Doesn’t give a numerical field value.

Field Indicator (Burmaplate) (Qualitative Direction):

Tool: Thin ferromagnetic sheet (often etched with a grid).

Method: Place the sheet on the part surface. Apply particles during magnetization. Particles will align along the magnetic flux lines, revealing the field direction pattern.

Purpose: Primarily visualizes the direction and general pattern of the magnetic field lines at the surface.

Advantages: Excellent for confirming proper field orientation (e.g., longitudinal vs. circular). Simple.

Limitations: Does not indicate field strength. Pattern can be distorted near edges or changes in geometry.

Magnetizing Current Verification (Indirect Assurance):

Tool: Calibrated ammeter (clip-on or in-line) and voltmeter.

Method: Measure the magnetizing current (A) and voltage (V) output of the equipment during magnetization cycles. Compare readings to equipment settings and calibration certificates. Verify timer accuracy.

Purpose: Ensures the equipment is delivering the input (current) specified by the procedure, which should theoretically generate the required magnetic field if applied correctly to the part.

Requirements: Current must meet the levels specified in the written procedure (based on part size, material, technique).

Advantages: Verifies the machine’s electrical output is correct.

Limitations: Does not measure the actual magnetic field on the part. Field strength depends heavily on part geometry, material permeability, contact resistance (prods), and lift-off (coils/yokes). Correct current does not guarantee correct field on the part. Must be used in conjunction with other methods (like Tangential Field or Indicators).

Critical Considerations:

Field Direction: Detection of discontinuities is maximized when the magnetic field is perpendicular (≥45°) to the expected flaw orientation. Direction must be verified (Pie gauge, Field Indicator).

Field Strength: Must be sufficient to create detectable leakage fields but not so high as to cause excessive background particle adherence masking indications.

Coverage: The magnetic field must adequately cover the entire area being inspected.

Calibration: All measuring instruments (Gaussmeter, Ammeter, Timer) must be calibrated traceably to national standards at specified intervals.

Procedure: Always follow the specific requirements of the applicable standard (ASTM, ISO, EN, ASME, etc.) and the written testing procedure.

Surface Condition: Field measurements/verification are significantly affected by surface roughness, coatings, and lift-off. Ensure good contact or account for lift-off per the meter’s instructions.

Technique Specificity: Verification method suitability depends on the magnetization technique (e.g., prod placement drastically affects field, coil fill factor is critical).

Best Practice: A robust verification program typically combines methods:

Use an ammeter to ensure correct machine output.

Use a tangential field probe for critical applications or complex parts to measure actual surface field strength.

Regularly use a Pie gauge or Ketos ring to confirm detection sensitivity and field direction across the inspection area.

Use a field indicator to visualize field patterns when setting up new or complex inspections.